Home > Product > PLC programmable module > KLA Tencor 073-652839-00 Controller Module

KLA Tencor 073-652839-00 Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:073-652839-00

- Get the latest price:Click to consult

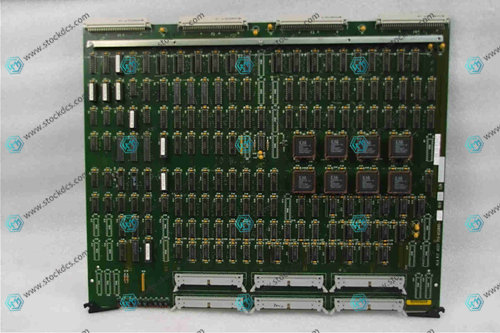

KLA Tencor 073-652839-00 Controller Module

Product Details Introduction

Introduction to KLA Tencor 073-652839-00 Controller Module

This module is the core control unit used by KLA Tencor for wafer surface inspection equipment, commonly referred to as RIF Board(Reflective Imaging Filter Board), Mainly integrated into various Surfscan series detection instruments (such as Surfscan 2132, 2138, 2139, eS31, etc.).

major function

Image acquisition and processing

This module is responsible for receiving and processing high-resolution image data from reflected light on the wafer surface. Through advanced signal processing technology, the module can effectively enhance image quality and assist backend systems in precise defect detection and classification.

Reflective imaging filter control

The module controls the position and state of the reflective imaging filter to achieve optical filtering functions at different wavelengths, in order to adjust imaging parameters for different detection needs and improve detection sensitivity and accuracy.

Multi module communication interface

The controller module has multiple communication interfaces, which can achieve high-speed data exchange with other modules within the device (such as data acquisition module, main control board, storage unit, etc.), ensuring overall coordination and smooth information flow of the detection system.

System stability and security assurance

When designing, attention should be paid to anti-interference ability and stability to ensure the reliability of equipment during long-term continuous operation and reduce the risk of downtime caused by electronic failures.

Equipment maintenance and upgrade support

The modular design of this module structure facilitates quick replacement or upgrade by maintenance personnel, greatly reducing equipment maintenance time and complexity, and improving the overall efficiency of the production line.

application area

Semiconductor wafer defect detection

As an important component in wafer inspection equipment, this module is widely used for real-time detection and quality control of wafer surface defects in semiconductor manufacturing processes, helping manufacturers ensure product yield.

Optical imaging system control

Control imaging filters, optimize optical detection conditions, and adapt to different types of wafer materials and detection processes.

System integration of high-precision detection equipment

As a key control unit of the system, participate in the electronic information processing and coordinated management of the entire detection instrument.

FEATURES

Support high-speed image data processing, low latency, fast response

Multi channel input, supporting multiple sensor interfaces

Equipped with anti electromagnetic interference design, suitable for industrial environments

Compatible with multiple Surfscan device models, with good scalability

Modular design for quick on-site maintenance and replacement

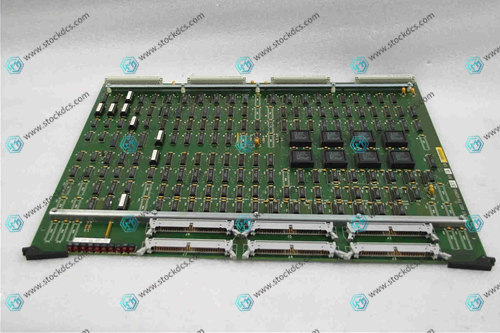

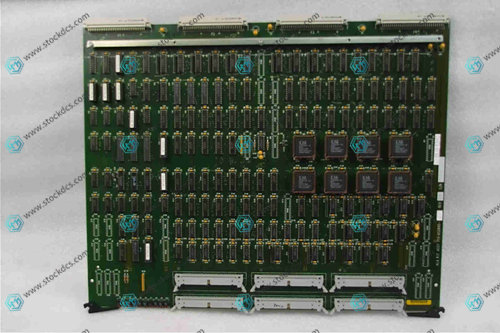

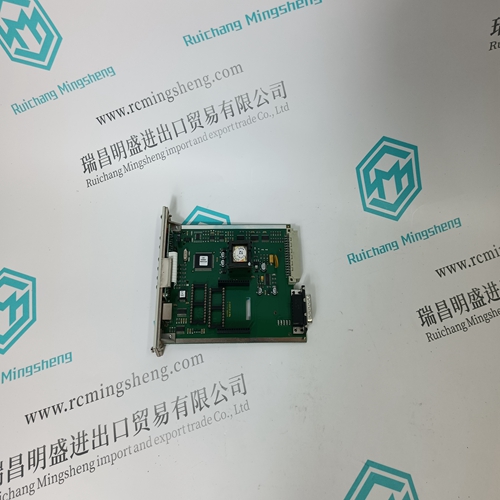

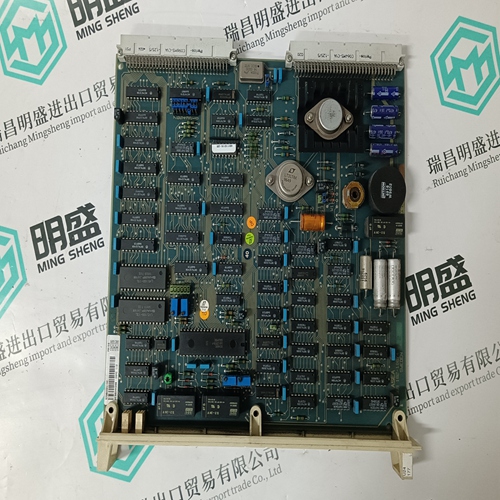

Product imag

Related website links

ADLINK CPS-H325/24 power module

ASEA YM316001-NL Double Plate Component

Foxboro FBM230 Communication Module

Other website links

| PMB33F-10114-03 | IMDSO04 | 3BSE012868R1 CI626V1 |

| PMB33F-10114-02 | 07EA80 | P21NRLA-LNN-NS-00 |

| PMB33F-10114-01 | IMAMM03 | 3BSE003848R1 |

| PMB33F-10114-00 | AMAT 0100-90941 | 57160001-ZL DSTD W113 |

| PMB33F-10101-03 | 07BE62R1 | P22NSXA-LSS-SS-03 |

| PMB33F-10101-02 | IMCOM04 | 3BSE018312R1 DSTA 181 |

| PMB33F-10101-01 | DIO00 | 57160001-ACT DSDP 140 |

| PMB33F-10101-00 | 07EA90-S | P2HNRXC-LNN-NS-00 |