Home > Product > Robot control system > Tokyo Electron SBX08-00027-1 Ultrasonic Device

Tokyo Electron SBX08-00027-1 Ultrasonic Device

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

Tokyo Electron SBX08-00027-1 Ultrasonic Device

Product Details Introduction

The Tokyo Electron SBX08-000027-1 Ultrasonic Transformer/Cleaner Unit is a functional component used for ultrasonic cleaning or liquid processing modules in semiconductor processes. It is commonly used in applications such as cleaning, development, pre etching cleaning, or high-precision material surface treatment. This component is usually integrated into TEL's Wet Station or Clean Track series of developing machines.

1、 Product Function Overview

Equipment type: Ultrasonic cleaner/Ultrasonic cleaning head/Ultrasonic transducer

Main functions:

By using ultrasonic vibration to form tiny bubbles (cavitation effect) in the liquid, particles, pollutants, or residual glue attached to the surface of the wafer can be removed;

Realize contactless cleaning to ensure the integrity and cleanliness of the device structure;

Improve surface quality control before development or wet etching.

2、 Main application areas

1. Ultrasonic Wafer Cleaning

Used to remove particles, metal ions, and small pollutants from the surface of wafers;

Often used in conjunction with cleaning solutions such as deionized water (DIW), hydrofluoric acid (HF), and ozone water (SC1/SC2).

2. Post lithography development process

Remove residual photoresist and developer by-products;

Improve the cleanliness of graphic edges to avoid subsequent etching defects.

3. Cleaning after film deposition

Remove sediment residue or prevent pollutants from depositing at the edge of the wafer;

Can be used in the cleaning process of pre-processing or intermediate processing steps.

3、 Applicable device platform (example)

Equipment series application module

TEL Clean Track ACT12 developing unit, wafer cleaning chamber

TEL Clean Track Lithium post development cleaning/ultrasonic assisted delamination

Ultrasonic components for TEL Unity Wet System wet cleaning section or chemical treatment tank

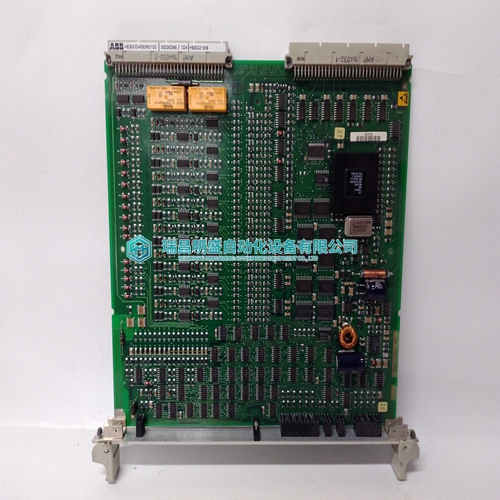

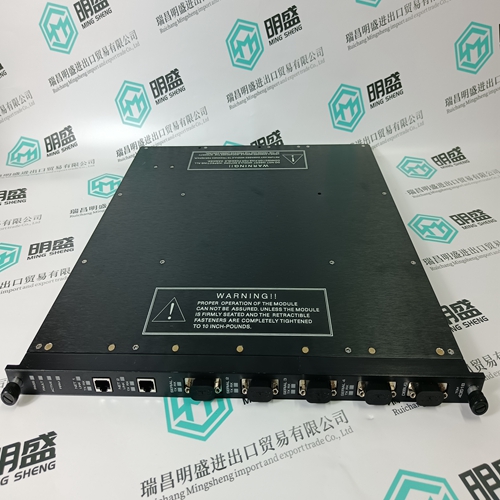

Product imag

Related website links

GE 151X1235DB15SA01 power converter

GE IS200TRLYH1B power converter

ASEA DSQC108 controller backplane

Other website links

| 139-NSF-V-TC | G310S230 | 710-604769-002 |

| 139-H-FLC-NFS | 5136-SD-VME | 710-603180-003 |

| 139-H-FLC | MMII-PD-1-2-120 | 208-500117-1 |

| 139-DO-NFS-FLC | MMII-PD-MOD522-240 | 710-102570-02 |

| 139-DO-FLC | 889-EP5P5G5LSSALAGAPFCSENNBN | 193X802DAG01 |

| 139-120V | 889-EP5P5G5HSSAANGMPFBSENNBN | 531X112PSAARG1 |