Home > Product > Robot control system > Sanyo Denki PZ0A100HP36SH0 servo controller

Sanyo Denki PZ0A100HP36SH0 servo controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PZ0A100HP36SH0

- Get the latest price:Click to consult

SANYO DENKI PZ0A100HP36SH0 servo controller

Product Details Introduction

High power adaptability: Sanyo Denki PZ0A100HP36SH0 servo controller can adapt to medium and high power servo motors, and can stably output strong power to meet the driving needs of heavy-duty automation equipment (such as large conveyor lines and heavy-duty machine tools).

Precise position control: Equipped with high-precision control algorithms, it can correct motor operating deviations in real time, achieve millimeter level positioning accuracy, and adapt to scenarios with strict position control requirements, such as precision component assembly equipment.

Modular design: Adopting a modular structure, the core components are independently arranged, which not only facilitates component replacement during later maintenance, but also flexibly expands functions according to equipment requirements, improving system adaptability.

Wide voltage adaptation: Supports a wide range of input voltages, can adapt to power grid fluctuations in different regions and industrial scenarios, avoid equipment downtime caused by voltage instability, and ensure production continuity.

Intelligent cooling system: Equipped with an efficient cooling fan and optimized cooling channels, it can automatically adjust the cooling intensity according to the operating temperature of the controller, avoiding performance degradation in high-temperature environments and extending the service life of the equipment.

Load adaptive regulation: With load monitoring function, it can automatically adjust output parameters according to the actual load changes of the motor, reduce energy consumption under light load, ensure sufficient power under heavy load, and balance energy saving and performance.

Industrial bus integration: Supports mainstream industrial bus protocols such as Profinet and Modbus, seamlessly integrates with factory automation management systems, enables real-time data exchange between controllers, upper computers, and other devices, and facilitates centralized control.

Machine tool processing adaptation: In the spindle drive system of CNC machine tools, the spindle speed and torque can be accurately controlled to ensure smooth cutting process and improve the surface smoothness and dimensional accuracy of workpiece processing.

Fault self diagnosis function: Equipped with a comprehensive fault detection module, it can monitor key parameters such as current, voltage, and temperature in real time. When abnormalities occur, it automatically alarms and records fault codes, simplifying the later troubleshooting process.

Anti vibration performance: The body adopts a reinforced structural design, which can resist equipment vibration interference in industrial workshops, ensure stable operation of internal circuits, and adapt to high-frequency vibration scenarios such as stamping machines and forging equipment.

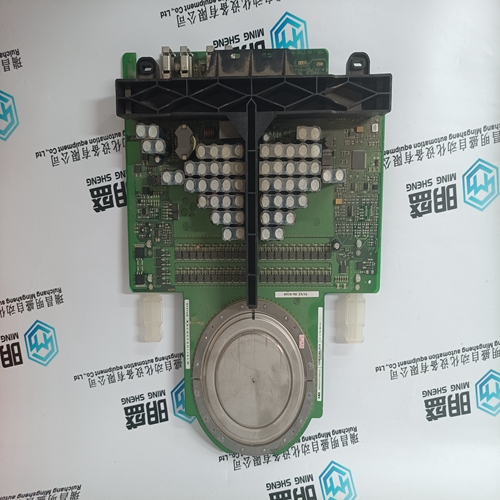

SANYO DENKI PZ0A100HP36SH0 Product imag

SANYO DENKI PZ0A100HP36SH0 Controller Module

YASKAWA JZNC-XPP02B Teaching pendant

YOKOGAWA YNT512D Overspeed Tachometer Module

ZNYX ZX370 Differential expansion module

Other website links

ICS TRIPLEX T8850 数字输入输出模块

ABB LDGRB-01 3BSE013177R1 控制器模块

ABB 07DC92D GJR5252200R0101 I/O 模块

| PMA42N-01100-00 | AMAT 0100-00048 | PFRL101A 0.5KN |

| PMA42N-00100-00 | AMAT 0100-01135 | PFRL101D |

| PMA42M-10100-00 | AMAT 0100-09041 | PFTL 101AE-0.5 |

| PMA42M-01100-00 | Amat 0100-03499 | PFTL 101BER-20.0KN |

| PMA42M-00100-00 | Amat 0100-35060 | PFTL 201DE-100.0KN |

| PMA24K-1050B-02 | Amat 0100-09320 | PFTL 201CE-10.0KN |