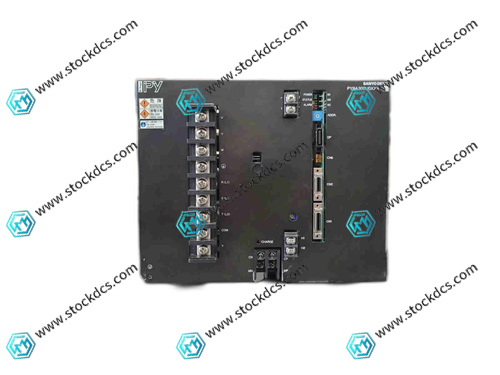

Home > Product > Servo control system > Sanyo Denki PY9A300U0XXXC07 servo controller

Sanyo Denki PY9A300U0XXXC07 servo controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PY9A300U0XXXC07

- Get the latest price:Click to consult

SANYO DENKI PY9A300U0XXXC07 servo controller

Product Details Introduction

High power and precise driving capability: As a high-power model of the PY series, PY9A300U0XXXC07 adopts high-performance power modules and advanced digital control algorithms, which can stably drive high-power servo motors (with an adaptation range covering kilowatts). In high-power driving scenarios such as heavy-duty CNC machine tools and large industrial robots, it can accurately output torque and speed, while balancing power intensity and control accuracy.

High frequency dynamic response performance: Equipped with a high-speed digital signal processor (DSP), the control cycle is as short as microseconds, which can quickly capture changes in the motor's operating status. The response delay to position and speed commands is extremely low. In scenarios such as high-speed stamping and precision assembly that require rapid action switching, it can achieve instruction following without lag, improving equipment operating efficiency.

Multi mode flexible control switching: supports three core control modes: position, speed, and torque, and can seamlessly switch modes through external signals or parameter settings. It can meet the micro level positioning requirements of precision machine tools and adapt to constant torque drive scenarios of heavy-duty conveyor belts, flexibly responding to diverse industrial working conditions.

Wide range motor compatibility and adaptation: Not only can it seamlessly match servo motors of the same brand such as Q series and P series, but it is also compatible with third-party high-power servo motors that meet industry standard interfaces. When upgrading equipment or replacing motors, there is no need for large-scale hardware modification, only simple parameter debugging is needed for adaptation, greatly reducing adaptation costs and downtime.

Intelligent adaptive optimization function: Equipped with automatic gain control (AGC) and load observer, it can monitor load fluctuations and operational disturbances in real time, automatically optimize control parameters, suppress vibration and noise, and maintain stable system operation even in scenarios with frequent load changes (such as material handling start stop), reducing manual debugging frequency.

Efficient energy saving and energy recovery: optimize IGBT driving efficiency, reduce controller no-load and operating energy consumption; At the same time, it is equipped with an efficient regenerative energy processing unit, which can feedback the excess energy generated by motor braking to the power grid or consume it in the braking resistor. Compared with traditional controllers, energy consumption is reduced by more than 15%, and long-term operation can significantly save energy costs.

Durable design for harsh environments: Adopting a high protection level shell (protection level up to IP40 or above), it can resist dust and moisture interference in industrial sites; Combined with an efficient cooling system, it can work stably in environments with temperatures ranging from 0-55 ℃ and humidity levels of 20% -85% (without condensation), and is suitable for complex industrial scenarios such as machine tool workshops and metallurgical plants.

Comprehensive safety and operation guarantee: integrating multiple safety functions such as overcurrent, overvoltage, overheating, overload, and motor phase loss protection. Under abnormal working conditions, the output can be quickly cut off and an alarm can be triggered to prevent equipment damage; At the same time, it supports software monitoring and fault diagnosis on the computer side, allowing real-time viewing of operating data and storage of parameters, facilitating quick troubleshooting and shortening operation and maintenance time.

SANYO DENKI PY9A300U0XXXC07 Product imag

SANYO DENKI PY9A300U0XXXC07 Controller Module

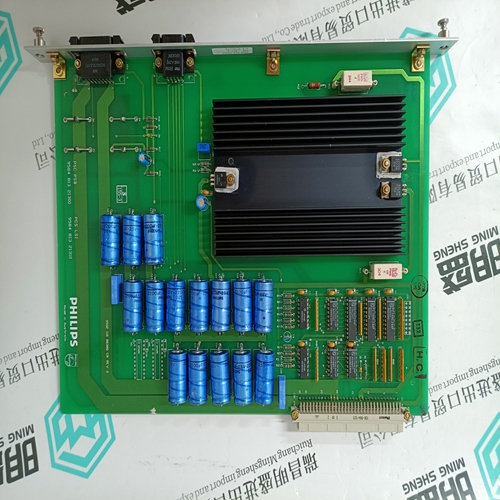

ABB 1VCR000993G0002 Line interface module

ABB 3HAC041443-003 Computer unit

ABB 3HAC16831-1 Battery pack

Other website links

A-B 1756-TBCH 伺服电机

ABB 3BHE046836R0102 GFD563A102编程逻辑控制器

EMERSON 9199-00002A6120 监测模块

| 269PLUS-10C-120VAC | 51200-60 | 0-809156-000 |

| 269PLUS-10C-120 | 56PC-8908-NR | 710-300012-00 |

| 269PLUS-100P-HI | PIM153 | 712-404561-00 |

| 269PLUS-100P-120VAC | S60100-PB | 720-11774-001 |

| 269PLUS-100P-120AC | SS410-10002 | 720-24609-000 |

| 269PLUS-100P-120 | SS9RMP | 710-679375-002 |

| 269PLUS-100N-120 | SV3440-01000 | 92-005649-XXX |