Home > Product > Robot control system > Sanyo Denki Q1AA13500DXP00 Spindle Motor

Sanyo Denki Q1AA13500DXP00 Spindle Motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:Q1AA13500DXP00

- Get the latest price:Click to consult

SANYO DENKI Q1AA13500DXP00 Spindle Motor

Product Details Introduction

High power density power output: As a representative model of Q-series spindle motors, Q1AA13500DXP00 adopts optimized electromagnetic winding and magnetic steel layout design to achieve efficient power conversion in a compact body. The rated power is suitable for medium and high power application scenarios, and can provide continuous and stable power for CNC machine cutting and precision machining equipment spindles, balancing power intensity and operating efficiency.

Micron level spindle positioning accuracy: Equipped with a high-resolution absolute value encoder (reference series high-precision feedback configuration), combined with a fully closed-loop feedback control system, the positioning error can be controlled at the micrometer level. In scenarios such as mold precision milling and semiconductor device processing, the spindle rotation position and feed coordination can be accurately controlled, greatly improving the machining accuracy and surface smoothness of workpieces.

Wide speed range smooth operation characteristics: The speed adjustment range covers the low-speed constant torque to high-speed light load range, and the highest speed can reach thousands of revolutions per minute. By optimizing the rotor dynamic balance and cogging torque suppression technology, the speed fluctuation is significantly reduced during low-speed operation, and the vibration amplitude is small during high-speed operation, which is suitable for the machining needs of multi speed range switching such as precision grinding and high-speed cutting.

Strong controller compatibility and adaptability: It can seamlessly match Q series and PY series servo controllers of the same brand, without the need to adjust interface parameters to achieve linkage control. In the scenario of upgrading old equipment or replacing spindle motors, it can directly adapt to the original control system, reduce hardware modification and debugging costs, and shorten equipment downtime.

Low consumption and high-efficiency heat dissipation design: Using low loss electromagnetic materials and high-efficiency heat dissipation duct structure, the energy consumption of the motor during operation is reduced by more than 10% compared to traditional models. At the same time, the heat generated during operation can be quickly exported to avoid performance degradation caused by high temperature, ensuring the stable operation of the motor under long-term continuous processing conditions (such as batch part production).

Industrial environment resistant structural protection: The body adopts a high rigidity shell and sealed design, with a protection level of IP54 or above, which can resist environmental interference such as dust and coolant splashing in the processing workshop; Simultaneously optimize the selection of bearings, enhance wear and impact resistance, and adapt to complex industrial scenarios such as machine tool workshops and automotive parts processing.

Full dimensional safety protection mechanism: Built in overload, overcurrent, overheating, and overspeed protection modules. When the load exceeds the rated value, the speed is abnormal, or the temperature is too high, the protection function will be immediately triggered, cutting off the power output and sending an alarm signal to prevent motor burnout and related processing equipment damage, reducing production safety risks and maintenance costs.

Multi scenario processing adaptability: With balanced power performance and precise control characteristics, it is widely used in small and medium-sized CNC machine tool spindles, precision machining centers, textile machinery spindles, and other equipment. It can meet the processing needs of metal cutting, non-metallic material carving, and can also adapt to continuous production scenarios that require stable spindle speed. It is a highly reliable supporting component in the field of industrial automation processing.

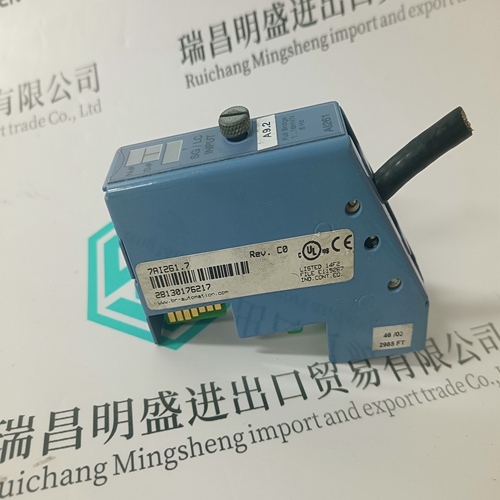

SANYO DENKI Q1AA13500DXP00 Product imag

SANYO DENKI Q1AA13500DXP00 Controller Module

A-B 2711-K10C20/E Touch screen

ABB 1VCR000993G0002 Line interface module

ABB 3HAC041443-003 Computer unit

Other website links

AB 1756-IF16A电压输入

A-B 1756-TBCH 伺服电机

ABB 3BHE046836R0102 GFD563A102编程逻辑控制器

| 269PLUS-120N-HI | PSX100 | 281-500305-3 |

| 269PLUS-120N-125VDC | P18003330RR | 531X309SPCAJG1 |

| 269PLUS-120N-120 | 51250-60 | F31X111PSHAFG1 |

| 269PLUS-10C-HI | P315MH422 | F31X111PSHAJG1 |

| 269PLUS-10C-48VDC | RP1001 | F31X174RCCADG1 |