Home > Product > PLC programmable module > Atlas Copco PF3109-G-HW processor

Atlas Copco PF3109-G-HW processor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PF3109-G-HW

- Get the latest price:Click to consult

Atlas Copco PF3109-G-HW processor

Product Details Introduction

1、 Product Overview

Atlas Copco PF3109-G-HW is a high-performance processor module in the PF3000 series, mainly used to drive and manage Atlas Copco's electric tightening tools (such as Tensor ST, ETX, STR series). This model is a "G" level (advanced) controller with multi tool support capabilities, integrating power supply, tightening program control, process monitoring, and industrial communication functions. It is the core control unit in industrial assembly automation.

Model Description:

PF3109: Tool that supports 9-level power range or larger torque range

G: Indicating enhanced functionality, support for multiple programs, MES connectivity and other extension capabilities

HW: Refers to the hardware standard configuration version

2、 Technical parameters (brief)

Compatible tools: Tensor ST, ETX, STR, EBL and other series of power tools

Tightening method: torque control/angle control/multi-stage/composite control

Communication protocols: Ethernet, RS232, I/O; Optional extension supports ProfiBus/DeviceNet/PROFINET

Program capacity: Supports management of hundreds of tightening programs

Focus recognition function: supports tightening point recognition (Focus Control)

Installation method: Standard industrial control cabinet or embedded production line installation

Other features:

Support fault identification (slipping teeth, missing twist, over twist)

Support tightening curve storage and export

Can be integrated with ToolsTalk PF software and MES/PLC systems

3、 Application Fields

1. Automobile manufacturing

Tightening control of key connectors used in assembly lines such as engines, suspensions, and transmission systems

Suitable for flexible production environments that require multi-channel and multi station operations

Integrate with MES system to achieve one-to-one correspondence between vehicle body number and tightening data

2. New energy vehicle industry

Tightening of battery module structure, precise connection of electric drive system casing and electronic control device

Multi station parallel operation, focus recognition, and program switching functions in high-speed assembly lines

3. Rail transit and heavy industrial equipment

High torque control of heavy-duty threaded connections such as vehicle structure, shock absorbers, and braking systems

Support high load continuous operation of medium and large tools, suitable for harsh industrial environments

4. Industrial automation and robot assembly line

As the core controller of the robot tightening workstation, it realizes intelligent management of the tightening workstation

Multiple tightening programs automatically switch to adapt to different workpiece models and positions

5. Home appliances and electronics manufacturing

Bolt connection process control for large household appliances such as washing machines and air conditioners

Support small torque tightening tasks with high tempo and high repeatability accuracy

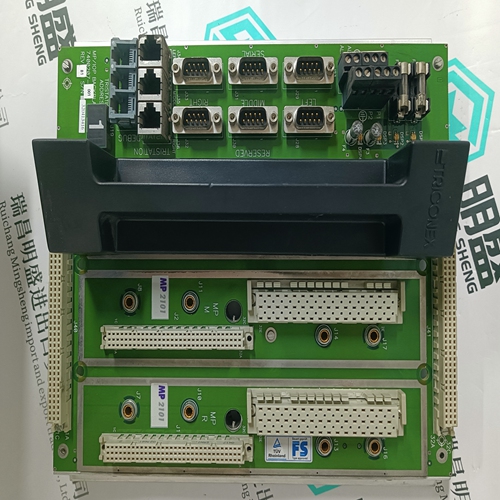

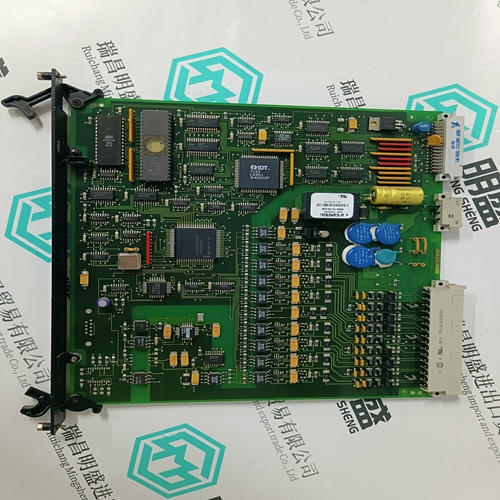

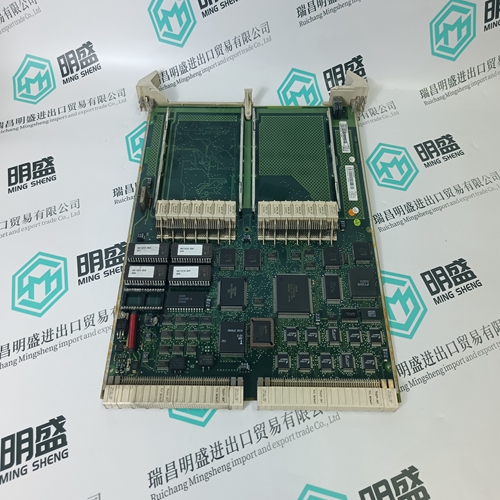

Product imag

Related website links

AMAT 0190-11415 Digital Input Module

GE D20 EME 10BASE-T Digital Control Modu

RADISYS 451558-004 Communication Module

Other website links

| 2VM61-020-2 | PSR45A-220 | IC3600TPSE1 |

| 2VM61-020-14 | PSR3-20850-01-003 | IC3600TPSC1 |

| 2VM61-020-13 | S62000 | IC3600TPSB1B |

| 2VM61-000-3 | PPC611100 | IC3600TPSB1 |

| 2VM61-000-2 | SR1000-000000 | IMDSM05 |

| 2VM61-000-1 | PSR3-23075-25-202 | 710-658268-20 |