Home > Product > Servo control system > Atlas Copco PF3109-C-DN-HW Drive Unit Controller

Atlas Copco PF3109-C-DN-HW Drive Unit Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

Atlas Copco PF3109-C-DN-HW Drive Unit Controller

Product Details Introduction

1、 Product Overview

Atlas Copco PF3109-C-DN-HW is an intelligent power tool drive controller for the mid to high torque range in the Power Focus 3100 series. It is used to control the Atlas Copco Tensor series electric tightening tools, achieve precise torque and angle control, support industrial bus communication and highly integrated tightening program management, and is widely used in automated assembly lines that require high quality tightening of connectors.

Interpretation of Model Meaning:

PF3109: PF3100 series medium to high power models, suitable for high load tightening tools

C: Standard control version, suitable for the vast majority of industrial control applications

DN: Integrated DeviceNet communication interface

HW: Hardware Version

2、 Core technical parameters

Project Specification Description

Support tools such as Tensor ST, STR, SL, EBL, ETX series and other high torque tools

Power input AC 100-240V, 50/60Hz, single-phase

Control functions include torque control, angle control, angle monitoring, multi-stage tightening control

Maximum number of programs ≥ 255 independently configurable tightening programs

Communication methods: DeviceNet (integrated), Ethernet, serial port, digital I/O

Tighten the support for real-time data collection, curve storage, local and network uploading

Installation method: DIN rail installation or panel embedded installation inside the control cabinet

3、 Typical application areas

1. Assembly of the entire car and its components

Tightening of key bolts for engine, chassis, suspension, electric drive structural components, etc

Workstation level controller, combined with main control PLC/MES to achieve multi workstation collaborative control

2. New energy vehicles and power battery industry

High precision torque assembly of battery casing, module assembly, and electronic control unit

Support data integration with MES platform to achieve product level traceability management

3. Intelligent automated tightening system

Collaborate with robots to achieve automatic bolt recognition and program calling

Tightening action and position information linkage control to improve job consistency

4. Construction machinery and heavy industry assembly

Connection control of large structural components, such as flanges, frames, and joint parts

To meet the demand for high-precision continuous tightening under heavy loads

5. Manufacturing of household appliances and consumer electronics

Precision tightening of product casing, motor components, and fixed structural components

Quickly switch production modes, suitable for flexible assembly processes

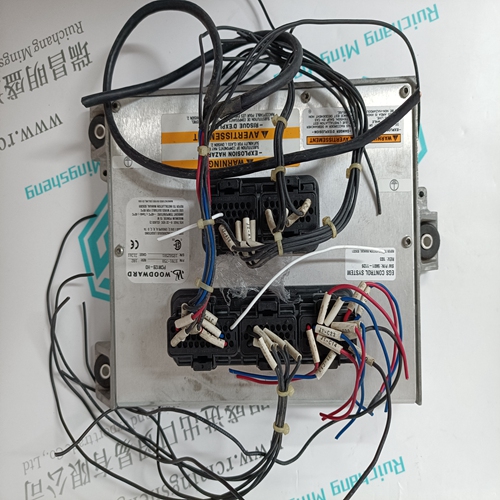

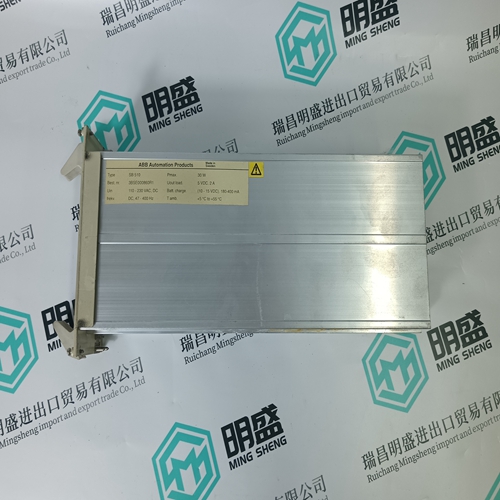

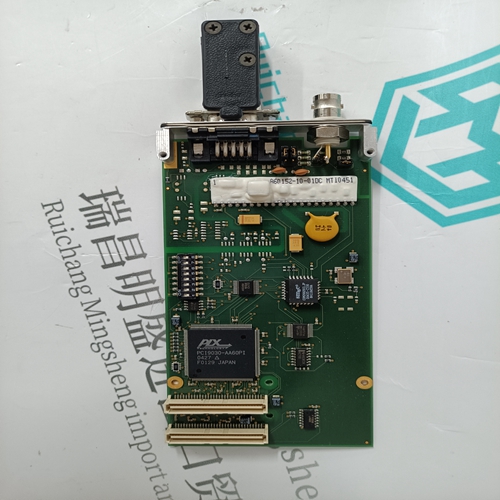

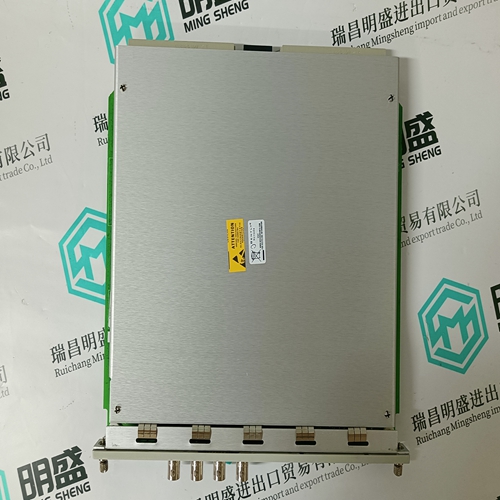

Product imag

Related website links

ABB XVC768115 thyristor module

RADISYS 061-01450-0010 Network Adapter

Other website links

| 269PLUS-10C-120 | 56PC-8908-NR | 710-300012-00 |

| 269PLUS-100P-HI | PIM153 | 712-404561-00 |

| 269PLUS-100P-120VAC | S60100-PB | 720-11774-001 |

| 269PLUS-100P-120AC | SS410-10002 | 720-24609-000 |

| 269PLUS-100P-120 | SS9RMP | 710-679375-002 |

| 269PLUS-100N-120 | SV3440-01000 | 92-005649-XXX |

| 269-120N-120VAC | S5101 | 710-611536-000 |