Home > Product > DCS control system > ZYGO 7702 BH5-6314 laser head

ZYGO 7702 BH5-6314 laser head

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

ZYGO 7702 BH5-6314 laser head

Product Details Introduction

ZYGO 7702 BH5-6314 laser head is a high-precision dual frequency helium neon laser interferometric measurement light source, mainly used for precision measurement and displacement tracking. It has a wide range of applications, covering high demand industries such as semiconductor manufacturing, precision machining, and metrology calibration. The following are its main application areas and detailed introduction:

1. Semiconductor manufacturing and photolithography process

In the semiconductor industry, nanoscale measurement accuracy is crucial, and the ZYGO 7702 BH5-6314 laser head plays a key role in the following aspects:

Lithography machine alignment: used for wafer alignment and position feedback to ensure precise stacking of each layer circuit pattern.

Wafer positioning and motion control: Monitor the nanoscale movement of the wafer stage to improve exposure accuracy.

Mask alignment: used for precise positioning of photomask templates to reduce errors.

Wafer flatness detection: used to measure the warpage of wafers and optimize production processes.

2. Precision metrology and interferometry

ZYGO laser heads are widely used in precision interferometric measuring instruments, such as white light interferometers, contour measuring instruments, etc., and are suitable for:

Nanoscale length measurement: used in metrology laboratories for high-precision length benchmark measurement, such as calibration blocks, rulers, interferometers, etc.

Surface morphology detection: detecting the surface roughness and shape errors of optical components, lenses, and glass substrates.

Non contact measurement: avoids the errors of traditional mechanical measurement and improves measurement accuracy.

3. Precision machining and CNC control

High precision feedback systems are required for manufacturing systems such as high-end machine tools and CNC equipment. ZYGO 7702 BH5-6314 can be used for:

High precision position feedback for CNC machine tools, such as five axis machining centers and ultra precision turning machines.

Tool displacement monitoring: Ensure that the tool cuts with nanometer level accuracy, improving machining consistency.

Part size control: used for online inspection to ensure that processed parts meet tolerance requirements.

4. Manufacturing and testing of optical components

In the field of high-end optical manufacturing, this laser head is used to measure the surface quality and optical parameters of lenses, mirrors, fibers, etc

Laser interferometer: measures the surface flatness of lenses, prisms, and mirrors.

Free surface detection: detection of high-precision optical components such as car headlight lenses and projection lenses.

Glass and display panel measurement: used for measuring the warpage and thickness of OLED and LCD panels.

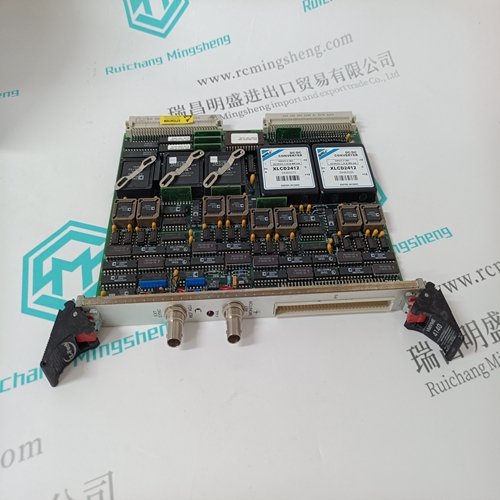

Product imag

Related website links

Fanuc A06B-6114-H205 servo amplifier

Fanuc A06B-6115-H006 servo drive

GE 151X1235DB15SA01 power converter

Other website links

| BA3624-7024-9-56BC | AMAT 0100-71224 | 21660559-H DSRA110 ABB |

| BA3624-7005-9-56BC | AMAT 0100-01467 | PFCL201CD/CE |

| BA3624-5558-56B | AMAT 0100-01401 | 57360001-DC DSMC120 ABB |

| BA3618-7009-9-56BC | AMAT 0100-71320 | 5735099-BA DSIH71 ABB |

| BA3618-7009-9-48B | AMAT 0100-AE018 | 48980002-A DSSB120 ABB |

| BA3616-7035-10-48C | AMAT 0100-01339 | 57360001-HC DSMC112 ABB |

| BA3614-5034 | AMAT 0100-09213 | 57360001-K DSMB151 ABB |

| BA3614-4648-9-56BC | AMAT 0100-09307 | PFEA101 |