Home > Product > Servo control system > TOYOTA 24220-23300-71 Logic Board

TOYOTA 24220-23300-71 Logic Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:24220-23300-71

- Get the latest price:Click to consult

TOYOTA 24220-23300-71 Logic Board

Product Details Introduction

TOYOTA 24220-23300-71 Logic Board

Product Overview

The TOYOTA 24220-23300-71 logic board is one of the core control units of Toyota electric forklifts, used to process driver operation signals, sensor data, and send execution instructions to the drive system, hydraulic system, and auxiliary equipment. This logic board is a key component of the forklift electronic control system, ensuring precise operation, system stability, and achieving safety protection functions.

Product Features

High performance signal processing

Quickly receive and analyze signals from handles, pedals, and sensors to ensure immediate execution of control commands.

integrated design

Concentrate logical operations, signal acquisition, and output control on one board, simplify wiring, and improve system reliability.

Industrial grade durability

By using electronic components that are resistant to high temperatures, vibrations, and interference, they can operate for a long time in complex industrial environments.

Safety protection function

Built in overcurrent, overvoltage, overheating, and limit detection mechanisms improve the safety of forklift operations.

Modular maintenance design

The logic board can be quickly disassembled and replaced, making it easy to repair and maintain, and reducing downtime.

Strong compatibility

Specially designed for Toyota electric forklifts and related industrial vehicles, ensuring compatibility with the original vehicle control system interface and signals.

Product application areas

Electric forklift drive control

Control the start stop, acceleration/deceleration, and direction switching of the driving motor to achieve smooth driving.

Hydraulic system management

Coordinate the actions of the hydraulic pump and solenoid valve to achieve the lifting, tilting, and lateral movement of the fork.

Operation signal processing

Collect signals from the driver's operating handle, pedals, and buttons, convert them into control commands, and output them to the execution unit.

Security monitoring and protection

Real time monitoring of battery, motor, and sensor status, providing protective measures, and improving operational safety.

Auxiliary equipment management

Control auxiliary devices such as lights, buzzers, and display panels to enhance operational convenience and safety.

Application of industrial automation equipment

Can be used for centralized control and data processing of automated handling vehicles, stackers, and other industrial vehicles.

Product imag

Related website links

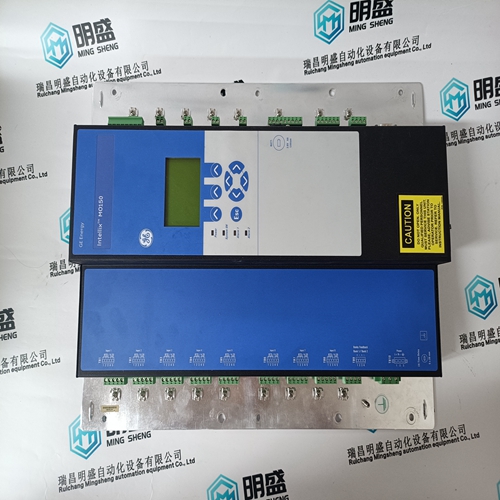

GE IS200TRLYH1B power converter

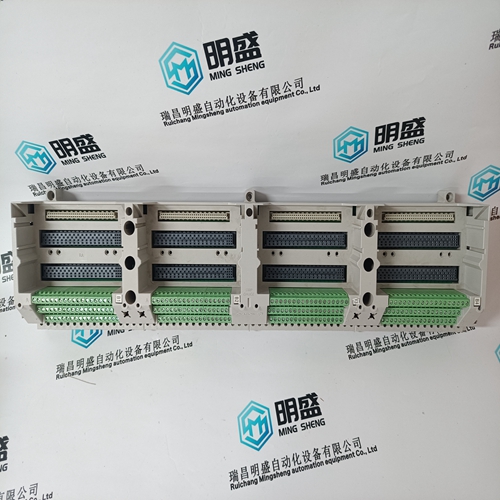

ASEA DSQC108 controller backplane

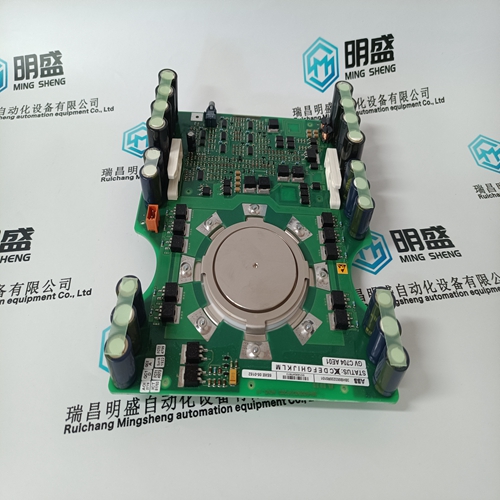

FOXBORO RH926GH Control Input Card

Other website links

IS400JPDHG1ABB IS410JPDHG1A轴速度反馈传感器

| AMAT 0100-90967 | TP-1554-3 | ALD-21 |

| AMAT 0100-00579 | TP-1554-4 | E48W-H16K |

| AMAT 0100-90971 | TP-1555-4 | 0-60063-1 |

| AMAT 0100-09114 | TP-1601-1 | FZ1200R12KF1 |

| AMAT 0100-09031 | TP-3844-1 | P0926GH |