Home > Product > Robot control system > TEL Tokyo Electron 381-500242-B Input/Output Module

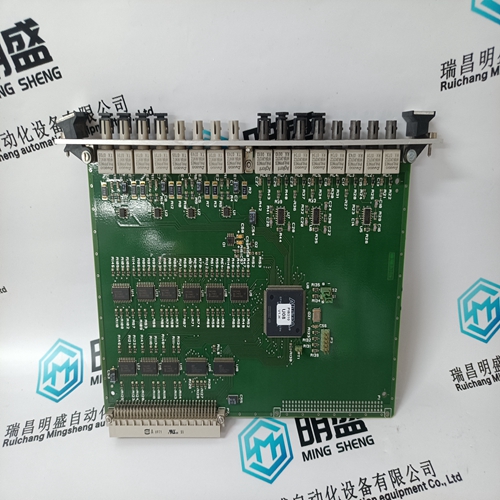

TEL Tokyo Electron 381-500242-B Input/Output Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

TEL Tokyo Electron 381-500242-B Input/Output Module

Product Details Introduction

The TEL Tokyo Electron 381-500242-B Input/Output Module (I/O Module) is one of the core functional components used in Tokyo Electron semiconductor manufacturing equipment for collecting and outputting control signals. This type of module is widely used in TEL's etching equipment (Etcher), CVD, ALD, lithography pre-processing and post-processing equipment, as well as transport systems (EFEM, Load Port). Its main function is to manage the signal interaction between various sensors and actuators related to equipment operation.

The following are detailed technical and application instructions without patterns:

1、 Basic Information

Product model: 381-500242-B

Product Name: I/O Module

Manufacturer: Tokyo Electron Ltd. (TEL)

Module Category: Control System I/O Board (Digital/Analog Input Output)

2、 Core functions

Input signal acquisition

Support the collection of digital or analog signals from limit switches, sensors, photodetectors, vacuum/temperature monitoring equipment, etc;

Real time transmission to the main controller for logical judgment and action triggering.

Output signal control

Output control signals to devices such as solenoid valves, relays, stepper drivers, heaters, etc;

Trigger automated actions (such as opening chamber doors, moving platforms, switching valves, etc.).

Signal isolation and anti-interference

Support electrical isolation design to ensure signal stability of equipment in high EMI environments;

Built in anti reverse and anti overload protection circuits.

System linkage and emergency control

Integrate with the main control system to achieve synchronous control of complex process flows;

Support safety interlock, emergency stop circuit, and status feedback processing.

3、 Typical application scenarios

Etcher equipment

Control gas valves, vacuum chamber doors, RF power supply linkage, monitor gas pressure/temperature and other status.

CVD/ALD system

Output gas path selection signal, input reaction chamber pressure and flow rate monitoring data.

Cleaning system

Control the inflow and outflow of medication, heating plate operation, drainage action, and monitor the liquid level and temperature.

Conveyor System (EFEM/Load Port)

Control the wafer transfer mechanism, alignment system, door lock system, and sensor status feedback.

Photolithography pre-processing and post-processing equipment

Control the start-up and status detection of the rotary table, heating and cooling device, and automatic alignment equipment.

Product imag

Related website links

GE IS210BPPBH2CAA Printed Circuit Board

GE IS200AEPAH1AFD Turbine Control Module

ASEA YT204001-BM Printed Circu

Other website links

ABB CHBX01R 2VAA008575R1 冗余模块底座

| PXIe-5172 | R34JMNC-R2-NS-NV-00 | R43HEBA-TS-NS-NV-00 |

| PXIe-5114 | R24HSNA-R1-NS-VS-06 | R45HCNA-R2-NS-VS-00 |

| PXIe-4610 | R43GENA-R2-NS-NV-07 | R32HSIC-TS-IS-1V-02 |

| PXIe-4480 | R23HENA-R1-NS-NV-01 | R33GEBC-R2-NS-VS-02 |

| PXIe-4145 | R34KENC-R2-NS-VS-00 | R43SSNA-HS-NS-NV-02 |

| PXIe-4141 | R34JENC-R2-NS-NV-00 | S31HNNA-RNNL-00 |