Home > Product > Gas turbine system > KLA Tencor 208-500686-1 processing module

KLA Tencor 208-500686-1 processing module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

KLA Tencor 208-500686-1 processing module

Product Details Introduction

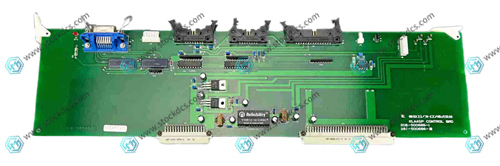

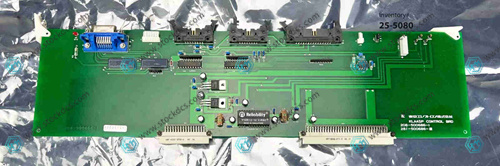

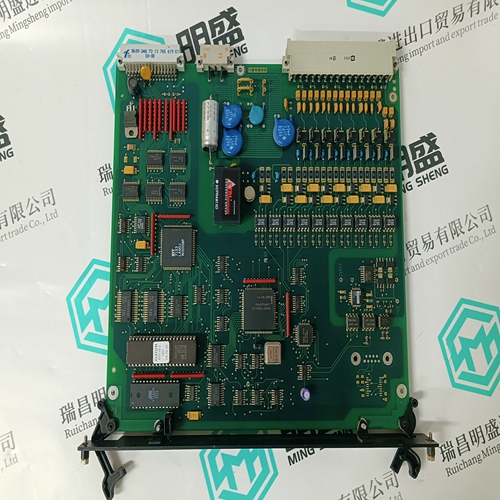

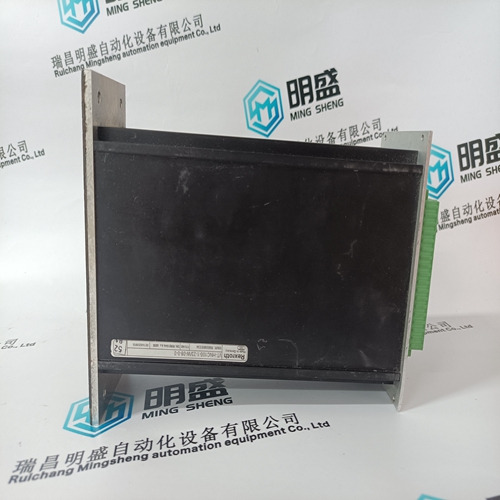

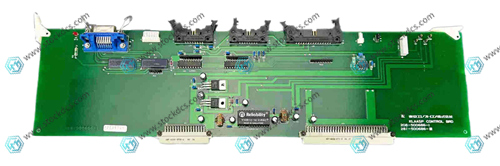

KLA Tencor 208-500686-1 Processing Module

product overview

The KLA Tencor 208-500686-1 processing module is the core computing and control unit in semiconductor testing equipment, responsible for a large amount of data processing and signal operation tasks. This module supports key functions such as image analysis, defect recognition, and motion control in wafer inspection systems through high-speed processing capabilities, ensuring overall equipment performance and detection accuracy.

major function

High speed data processing

Utilizing high-performance processor chips to process massive amounts of data transmitted from image acquisition systems in real-time, including image preprocessing, filtering, enhancement, and defect recognition.

Control signal generation

Based on the processing results, generate motion control instructions and feedback signals, coordinate the actions of various executing components of the equipment, and achieve precise synchronization.

Interfaces

Support data exchange and command communication with various peripherals such as the main control system, sensors, and drivers to ensure overall system collaboration efficiency.

diagnosis and monitoring

Built in status monitoring function, real-time detection of module operation status, timely alarm when abnormal, assisting maintenance and troubleshooting.

Technical Characteristics

Highly integrated design, integrating multiple high-speed interfaces and processing cores to enhance computing power.

Supports multiple industrial communication protocols, such as Ethernet, CAN, RS-485, etc., with strong compatibility.

Modular structure, convenient for maintenance and upgrading, shortening maintenance cycles.

Using industrial grade components, suitable for high cleanliness and temperature controlled environments, ensuring long-term stable operation.

Powerful real-time processing capability ensures high-speed computation and response of complex algorithms.

Typical application areas

Wafer inspection and analysis: Real time processing of image data, automatic identification and classification of defects.

Automatic Optical Inspection (AOI) equipment: supports high-precision image analysis and decision-making.

Motion control system: works in conjunction with single axis and multi axis controllers to achieve complex trajectory planning.

Equipment status monitoring and maintenance: Optimize equipment operation efficiency through built-in diagnostic functions.

Product imag

Related website links

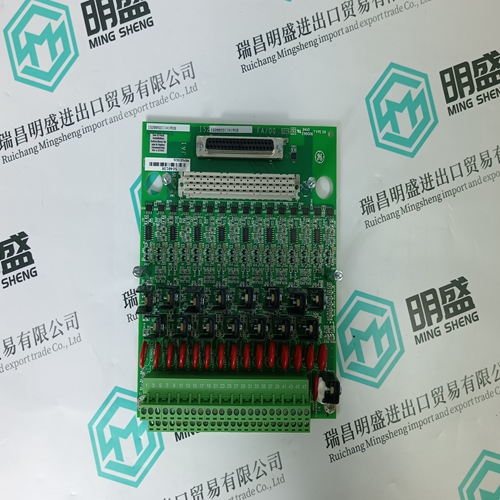

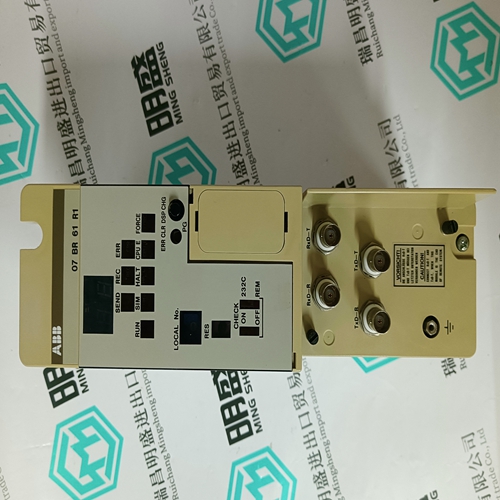

ABB XVC768117 Field Input/Output Module

Eaton XV-440-10TVB-1-50 Touch Screen

FOXBORO FBM217 Voltage Monitor Module

Other website links

GE VMIVME-017807-414001 直流信号输出模块

| PMB33E-10200-03 | AMAT 0100-00011 | PFTL101BER 2.0KN 3BSE023158R1 |

| PMB33E-10200-02 | AMAT 0100-11000 | PFTL101A 1.0KN 3BSE004166R1 |

| PMB33E-10200-01 | NICS01 | PMB33F-20216-03 |

| PMB33E-10200-00 | IIMKM01 | 57160001-GR DSTD 320 |

| PMB33E-10116-03 | 07AS82 | P21NRXB-LDN-PD-00 |

| PMB33E-10116-02 | 07BT62R1 | P22NSXC-LSN-NS-03 |

| PMB33E-10116-01 | NTLS01 | M22NRFA-LDS-NS-02 |

| PMB33E-10116-00 | AIN300 | 57120001-RF DSXW 111SG |