Home > Product > PLC programmable module > TEL Tokyo Electron CS1B85-372049-W1 motor impact module

TEL Tokyo Electron CS1B85-372049-W1 motor impact module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

TEL Tokyo Electron CS1B85-372049-W1 motor impact module

Product Details Introduction

Tokyo Electron (TEL) CS1B85-372049-W1 Motor Shock Module - Product Application Field Detailed Explanation

1. Wafer transfer system in semiconductor manufacturing equipment

Key role: This module is responsible for adjusting the impact force during the start and stop of the motor during wafer transfer, ensuring smooth movement of the wafer.

Application value: To prevent wafer displacement, damage, or positional deviation caused by impact or vibration during transmission, ensuring the integrity of the wafer and the stability of subsequent processes.

Typical scenarios: wafer handling robots, conveyor belt start/stop control, shock absorption optimization of conveying mechanisms, etc.

2. Automated mechanical motion control

Dynamic adjustment: This module optimizes the start and stop process of the robotic arm or conveyor system by controlling the motor impact.

Effect improvement: Effectively reduce the vibration and impact of the mechanical system, improve the smooth operation and repeated positioning accuracy of the equipment.

Application examples: Automated loaders, precision robotic arms, motor-driven conveyors, etc.

3. Equipment vibration suppression and performance optimization

Vibration buffering: By precisely controlling the impact force of the motor, the vibration caused by mechanical impact is reduced, and sensitive components inside the equipment are protected.

Extend lifespan: Effectively avoid mechanical fatigue and damage caused by frequent impacts, and extend the service life of equipment.

Easy maintenance: reduce failure rate, minimize maintenance frequency and downtime, and improve production line utilization rate.

4. High precision positioning system support

Smooth operation: Ensure smooth and stable operation during wafer loading, unloading, and handling to avoid positioning errors.

Process assurance: Stable positioning supports high-precision process execution, improving product yield.

Application environment: In situations where high-precision mechanical positioning is required, such as microfabrication equipment, lithography machines, etching equipment, etc.

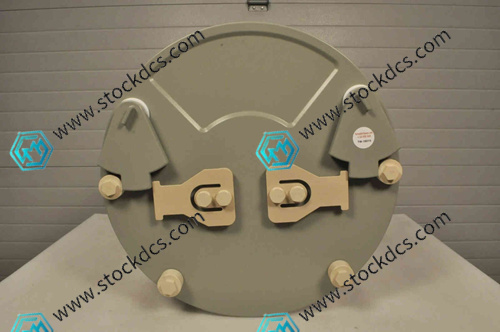

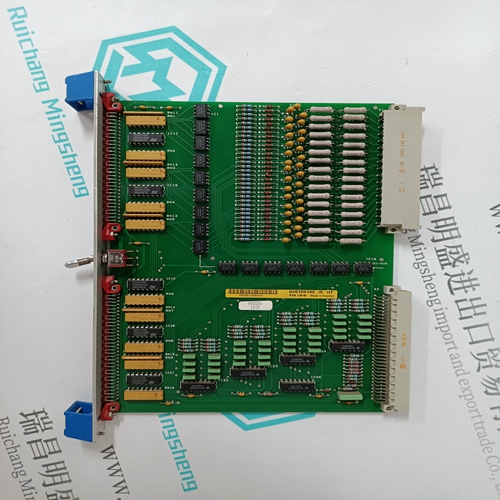

Product imag

Related website links

GE IS210BPPBH2BMD Controller Module

KOLLMORGEN CP310250 PRD-P310250Z-55 serv

Other website links

| 6ES5451-8MA12 | CACR-SR15BE12F | TRICONEX 3515 |

| 6ES5451-7LA21 | CACR-HR10SB | Asyst 3200-4348-04 |

| 6ES5451-4UA13 | CACR-HR15BB-Y81 | TRICONEX 3601T |

| 6ES5451-4UA12 | CACR-SR03BF1ESB | TRICONEX 3807 |

| 6ES5451-2CA11 | CACR-SR05BF1AFB | 6ES5242-1AA13 |

| 6ES5450-8MD11 | CACR-HR30BBY19 | 6ES5240-1AA11 |

| 6ES5450-8FA11 | CACR-IR010101FB | 6ES5470-7LA13 |